Transforming Sheet Metal Fabrication with Precision Technology

In today’s competitive manufacturing world, achieving flawless edge finishing is crucial, especially when working with sheet metal. Every cut, every fold, and every surface must meet tight tolerances and present a clean finish. This is where an AUTOMATIC DEBURRING MACHINE becomes a transformative asset. Designed to eliminate sharp edges, burrs, and micro-imperfections, this solution ensures each sheet metal component meets the highest quality standards.

Unmatched Efficiency and Consistency in Edge Finishing

Manual deburring is time-consuming and often leads to inconsistent outcomes. In contrast, an AUTOMATIC DEBURRING MACHINE delivers uniform results across all workpieces, regardless of complexity. Whether handling steel, aluminum, or stainless sheet metal, this technology adapts seamlessly to various thicknesses and contours, providing repeatable and dependable finishing. Consistency is key in mass production, and with automation, manufacturers can ensure every component leaves the line burr-free and ready for use.

Enhancing Workflow and Reducing Rework

An AUTOMATIC DEBURRING MACHINE not only boosts output speed but also drastically reduces errors that can lead to rework or part rejection. By automating the edge finishing process, manufacturers benefit from streamlined operations, reduced handling time, and improved productivity. The result is a more efficient manufacturing line with minimal downtime and higher overall equipment effectiveness, all while meeting stringent quality demands.

Designed for Modern Sheet Metal Needs

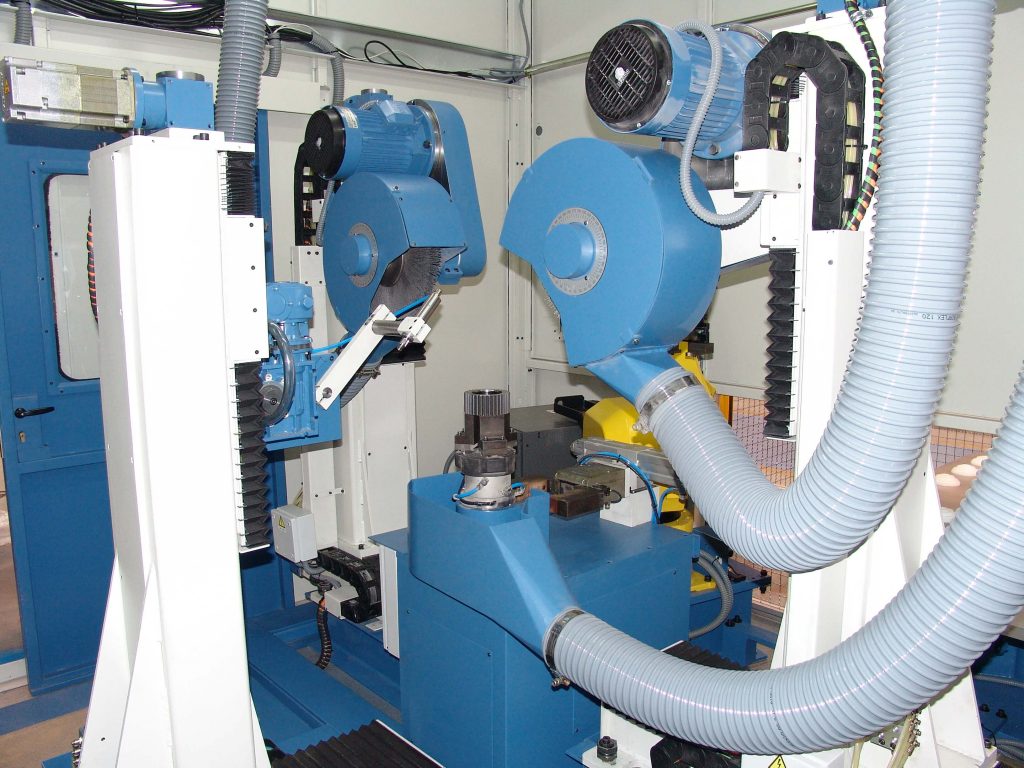

Today’s sheet metal applications range from lightweight automotive panels to high-precision enclosures used in electronics and industrial equipment. These components require smooth, clean edges to ensure proper assembly and long-term durability. An AUTOMATIC DEBURRING MACHINE is specifically engineered to meet these modern needs. Its brush systems, abrasive belts, and intelligent controls work together to provide a refined surface, ensuring every edge is safe, functional, and aesthetically finished.

Intelligent Automation for Superior Results

The latest generation of AUTOMATIC DEBURRING MACHINE technology integrates smart automation features such as programmable controls, load sensors, and real-time process monitoring. These innovations allow the machine to adapt automatically to different materials and part geometries without sacrificing performance. The operator can manage complex finishing tasks with minimal intervention, ensuring that even intricate parts receive uniform edge refinement with remarkable speed and accuracy.

Cost-Effective Solution for Long-Term Quality

Investing in an AUTOMATIC DEBURRING MACHINE is not just about improving quality—it also delivers significant cost savings over time. By minimizing labor, reducing scrap rates, and eliminating secondary operations, manufacturers can lower their production costs while maintaining high standards. These machines are built for durability, with robust components that stand up to heavy use, making them a reliable asset for long-term production environments.

Meeting Industry Demands with Technological Advancement

Industries such as automotive, HVAC, construction, and electronics depend heavily on sheet metal parts that are precisely finished. An AUTOMATIC DEBURRING MACHINE ensures these parts comply with both visual and functional standards. As industry expectations rise, manufacturers must equip their facilities with tools that deliver efficiency and quality without compromise. The combination of performance and adaptability makes these machines essential in high-demand environments.

Innovation Driven by Practical Manufacturing Challenges

Every production facility faces unique challenges, from varying material types to complex production schedules. An AUTOMATIC DEBURRING MACHINE addresses these real-world issues with configurable features and scalable options. Whether for batch processing or continuous operations, these machines offer unmatched flexibility, helping manufacturers handle diverse workloads while maintaining a competitive edge.

Elevating Sheet Metal Finishing to a New Standard

The pursuit of perfection in sheet metal fabrication is relentless. A clean, burr-free edge is not only a marker of quality but also a functional necessity. An AUTOMATIC DEBURRING MACHINE ensures that every component meets this standard with minimal effort and maximum precision. By embracing automation, manufacturers move closer to zero-defect production, elevate their brand reputation, and meet evolving customer expectations with confidence.